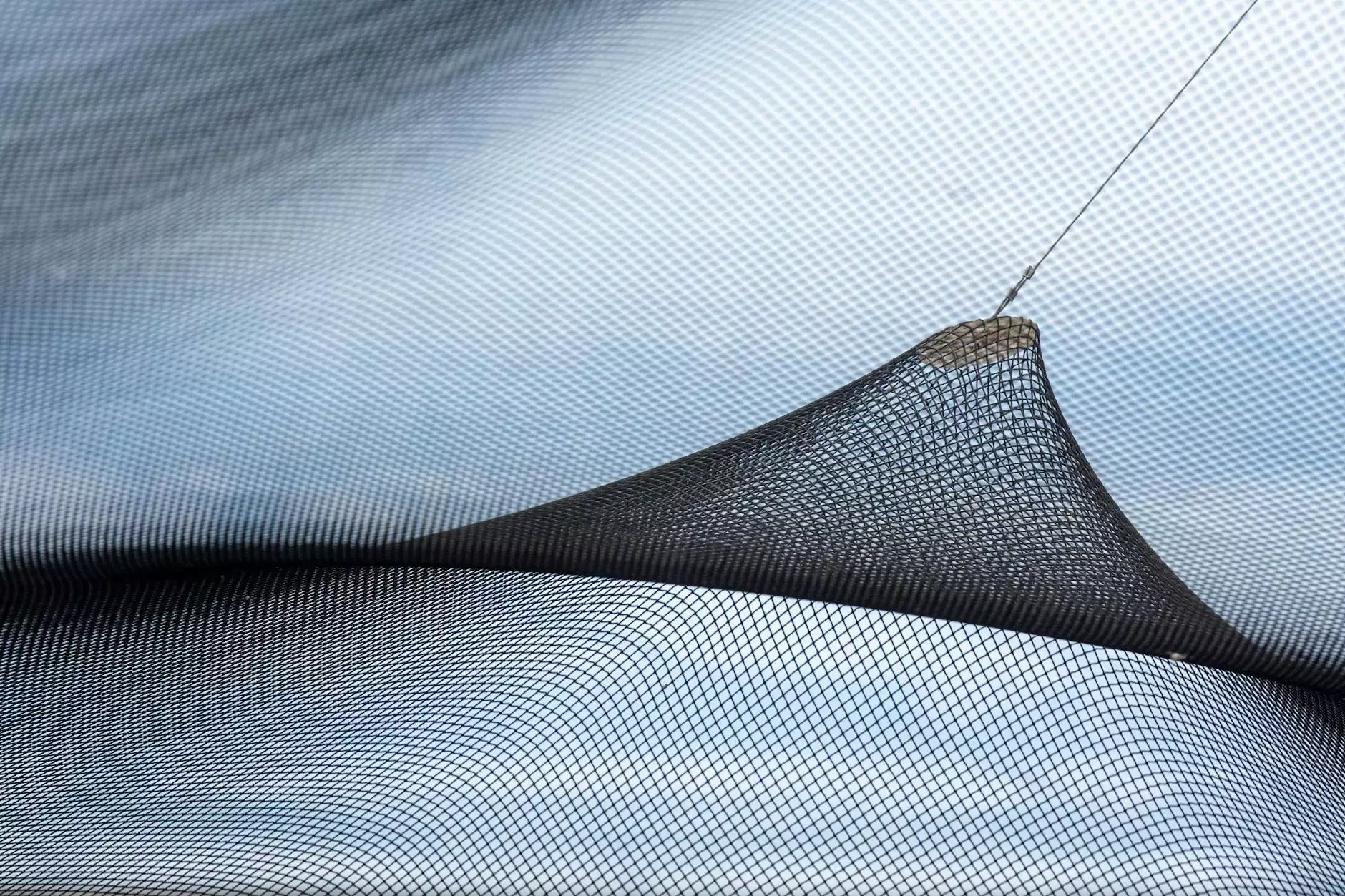

Enhancing Automotive Performance with Fiber for Car Applications

The automotive industry is witnessing a transformational shift towards advanced materials that not only enhance vehicle performance but also contribute to environmental sustainability. One of the most promising materials in this evolution is fiber for car applications. This article delves into the various aspects of fiber usage in automobiles, including its benefits, types, and future prospects. Whether you're an automotive enthusiast or a professional in the industry, understanding fiber materials can provide valuable insights into the future of vehicle design and functionality.

Understanding Fiber for Car Applications

In recent years, the automotive sector has increasingly adopted fiber-reinforced composites (FRC) due to their lightweight and high-strength properties. These materials are fundamentally changing the way vehicles are designed and manufactured, promoting higher performance while keeping production costs in check.

What is Fiber for Car?

Fiber for car refers to various types of reinforcement materials used in automotive manufacturing, including:

- Carbon Fiber: Known for its exceptional strength-to-weight ratio, carbon fiber is often used in high-performance vehicles.

- Glass Fiber: This cost-effective option is widely used in interior applications and decorative components.

- Natural Fibers: Sustainability-focused manufacturers are exploring options like hemp and flax fibers for eco-friendly vehicle structures.

The Benefits of Using Fiber in Automotive Design

Incorporating fiber materials in the automotive sector offers a multitude of advantages that are reshaping vehicle manufacturing:

1. Weight Reduction

One of the most significant benefits of fiber for car applications is weight reduction. Lighter vehicles provide better fuel efficiency, resulting in lower emissions and reduced environmental impact. For instance, by replacing metal components with carbon fiber, manufacturers can decrease the overall weight of the vehicle, enhancing performance and fuel economy.

2. Enhanced Durability

Fibers exhibit remarkable durability and resistance to fatigue. This increased longevity means fewer repairs and replacements over the vehicle's lifecycle, which translates to cost savings for both manufacturers and consumers.

3. Design Flexibility

Fiber-reinforced composites enable designers to craft more complex shapes and forms that would be difficult to achieve with traditional materials. This flexibility in design means vehicles can be more aerodynamic and stylish, appealing to modern consumer preferences.

Types of Fiber for Car Applications

Automotive manufacturers leverage various types of fibers, each with unique properties suited for different applications:

1. Carbon Fiber

Carbon fiber is a high-performance material known for its light weight and exceptional strength. It is often seen in luxury sports cars and racing vehicles, providing not only performance benefits but also aesthetic value due to its sleek appearance.

2. Glass Fiber

Glass fiber is more affordable than carbon fiber and is commonly used in mass-produced vehicles. Its versatility allows it to be used in body panels, hoods, and even certain structural components, offering a significant balance between cost and performance.

3. Natural Fibers

As sustainability becomes a key focus for consumers, natural fibers such as jute, hemp, and flax are gaining traction. These materials are renewable, biodegradable, and can reduce the vehicle's environmental footprint while maintaining performance standards.

Applications of Fiber Reinforcement in Vehicles

The integration of fiber materials is revolutionizing several components in automobiles:

- Body Panels: The use of fiber composites in body panels reduces weight while maintaining structural integrity.

- Interior Components: Lightweight fiber materials provide durability and design flexibility for dashboard inserts, door panels, and seating.

- Structural Reinforcement: Fibers are increasingly being utilized in critical structural components to enhance rigidity and safety.

Challenges and Considerations

While the advantages of using fiber for car applications are substantial, there are several challenges and considerations faced by manufacturers:

1. Cost of Production

Despite the benefits, high-quality fiber materials can be expensive to produce. This poses challenges for manufacturers striving to balance cost and performance.

2. Recycling and Disposal

The recycling of fiber composites is still a developing field, leading to questions about sustainability and the environmental impact at the end of a vehicle's life.

3. Manufacturing Techniques

Successfully integrating fiber materials into mainstream manufacturing requires advancements in production technologies and processes, which may take time to evolve.

The Future of Fiber in Automotive Engineering

Looking ahead, the future of fiber for car applications appears promising. With ongoing research and development, we can expect advancements in the processing, application, and recycling of fiber materials. Innovations like:

- Automated Fiber Placement: This technology allows for precise layering of fibers, improving material performance and reducing waste.

- Smart Materials: The development of fiber materials embedded with sensors could lead to enhanced monitoring of vehicle performance and health.

- Hybrid Fiber Composites: Combining different types of fibers may create materials that leverage the benefits of each type, leading to improved performance characteristics.

Conclusion

As consumers become more environmentally conscious and performance-driven, the automotive industry must adapt to these changing demands. Fiber for car applications represents a significant advancement in meeting these challenges. By utilizing fiber-reinforced materials, manufacturers can create vehicles that are not only luxurious and high-performing but also sustainable and efficient.

At customclass.net, we are committed to providing the latest insights and products in the automotive parts and supplies industry. Stay ahead of the curve by embracing the innovations that fiber for car applications brings to the table.