Maximizing Business Growth with China CNC Machining Parts Suppliers in the Metal Fabrication Industry

In today’s competitive manufacturing landscape, quality components, cost-efficiency, and reliable supply chains are critical elements for business success. The core of modern metal fabrication often lies in precise, durable, and innovative CNC machining parts. As global demand expands, many industry leaders turn to China CNC machining parts suppliers to meet their manufacturing needs. Among these suppliers, companies like DeepMould.net have distinguished themselves through unparalleled expertise, quality assurance, and customer-centric solutions.

Understanding the Role of CNC Machining in Metal Fabrication

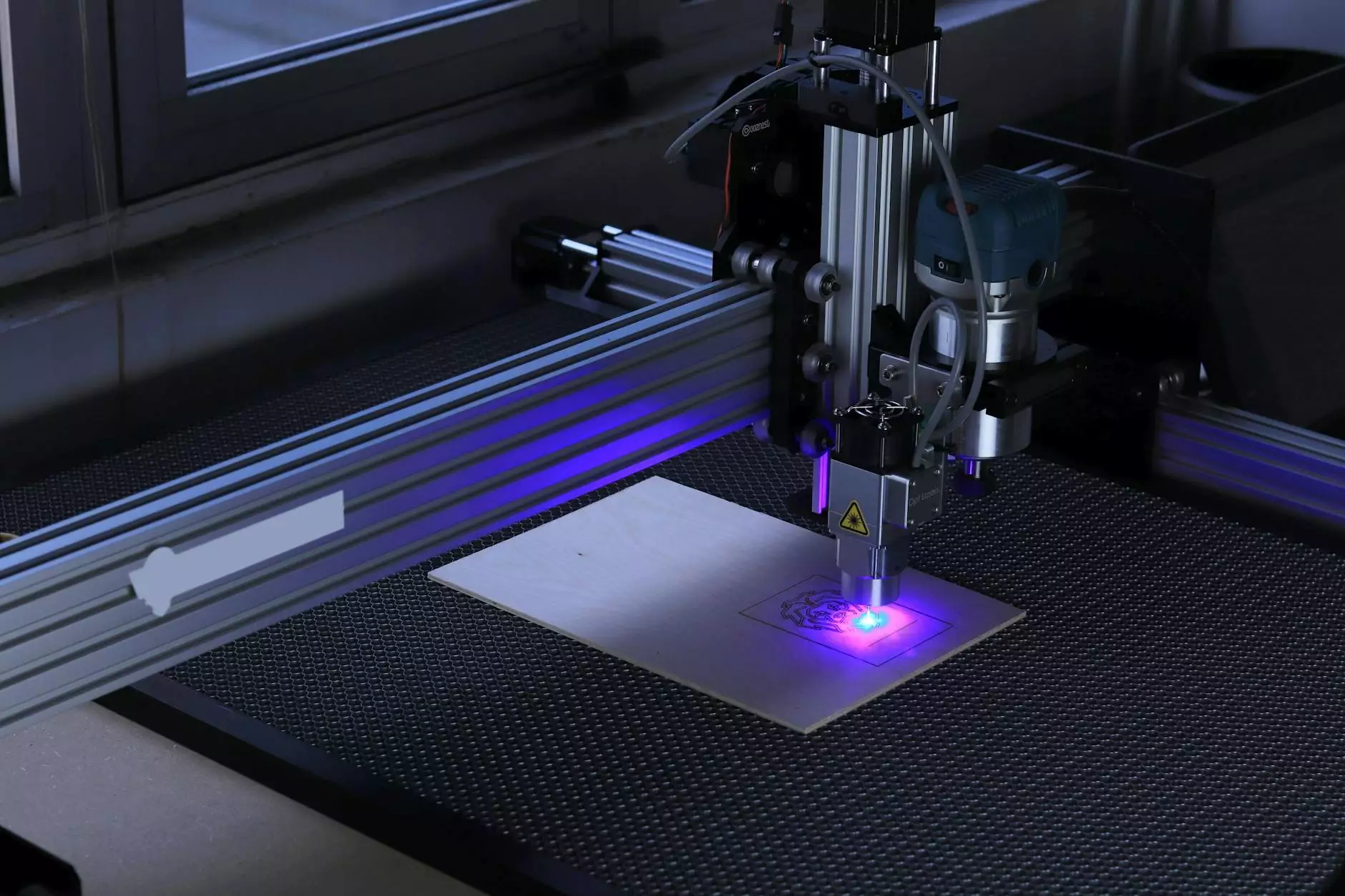

Computer Numerical Control (CNC) technology revolutionized metal fabrication by enabling highly precise, repeatable, and complex manufacturing processes. CNC machining involves automated control of machine tools such as mills, lathes, and grinders, which are used to produce intricate components with tight tolerances. This technology ensures that metal fabricators can produce parts that meet exact specifications, whether for aerospace, automotive, medical devices, or industrial equipment.

Leading china cnc machining parts suppliers leverage state-of-the-art CNC centers capable of working with a broad spectrum of metals, including stainless steel, aluminum, brass, titanium, and alloys. Their ability to customize designs, scale production, and maintain consistent quality makes them indispensable partners for metal fabricators aiming for operational excellence and outstanding product quality.

The Benefits of Partnering with China CNC Machining Parts Suppliers

- Cost-Effectiveness: Competitive raw material costs and efficient manufacturing processes allow Chinese suppliers to offer high-quality parts at significantly lower prices.

- High Precision and Quality: Modern CNC centers and adherence to international standards ensure parts meet stringent specifications.

- Wide Range of Materials and Finishes: Suppliers can work with diverse metals and provide various surface treatments, such as anodizing, plating, or coating.

- Scalability and Flexibility: Chinese suppliers accommodate both small batch prototypes and large-volume production runs, tailored to your project needs.

- Innovative Solutions: Many forward-thinking suppliers invest in R&D to develop advanced manufacturing techniques, enabling the creation of complex geometries and lightweight components.

Key Factors to Consider When Choosing China's CNC Machining Parts Suppliers for Your Metal Fabrication Business

Selecting the right supplier is crucial for ensuring product quality, delivery timelines, and overall cost efficiency. Here are vital criteria to evaluate:

1. Quality Assurance and Certification

Reputable suppliers possess certifications such as ISO 9001, IATF 16949 (automotive), or AS9100 (aerospace), demonstrating commitment to quality management and process control. Request detailed quality assurance reports and inquire about their inspection protocols, including coordinate measuring machine (CMM) checks and material testing.

2. Technological Capabilities

Ensure the supplier employs advanced CNC machines capable of executing complex multi-axis machining, 3D milling, and multi-material processing. Technological sophistication directly correlates with the ability to produce intricate, high-precision parts.

3. Flexibility and Lead Time

Assess their capacity to handle custom prototypes and large production volumes without compromising on delivery schedules. Suppliers with flexible production schedules and rapid prototyping capabilities can significantly accelerate your product development cycle.

4. Material Range and Finishing Options

Verify that they work with the specific materials your application requires and offer appropriate surface finishing options to meet performance or aesthetic requirements.

5. Communication and Customer Support

Effective communication channels, transparency, and proactive project management are essential. An experienced supplier will guide you through design optimization, material selection, and troubleshooting.

DeepMould.net: A Leading China CNC Machining Parts Supplier for Metal Fabricators

DeepMould.net stands out among china cnc machining parts suppliers by delivering exceptional manufacturing solutions tailored for metal fabricators worldwide. Their comprehensive approach combines cutting-edge CNC technology, rigorous quality management, and customer-centric service, making them a preferred partner for companies seeking reliable, high-quality metal components.

Why Choose DeepMould.net?

- Extensive Experience: Over a decade in CNC machining, specializing in complex and high-precision parts.

- State-of-the-Art Facilities: Equipped with multi-axis CNC machines capable of intricate geometries and fine detailing.

- Strict Quality Control: Certified processes, regular inspections, and adherence to international standards ensure top-tier product quality.

- Cost Leadership: Competitive pricing without compromising on quality, providing significant savings for your manufacturing budget.

- Customized Solutions: From prototypes to mass production, tailored to meet your specifications and deadlines.

How DeepMould.net Supports Your Metal Fabrication Business Growth

Partnering with DeepMould.net offers various strategic advantages:

Comprehensive Design Assistance

They collaborate with clients on design for manufacturability (DFM), optimizing parts for cost, strength, and manufacturability, thereby reducing production times and costs.

Material Versatility

They provide a wide selection of metal materials, from industrial-grade stainless steel to lightweight aluminum alloys, ensuring compatibility with diverse applications.

Advanced Finishing Options

Solutions such as anodizing, polishing, plating, and coating enhance functionality and appearance, vital for high-end industrial or aesthetic components.

Fast Turnaround & Reliable Delivery

Robust supply chain management and efficient production workflows enable timely fulfillment, ensuring your business maintains a competitive edge.

Future Trends in CNC Machining and Metal Fabrication

As the industry progresses, several innovations are shaping the future of china cnc machining parts suppliers and metal fabricators:

- Automation and Smart Manufacturing: Integration of AI, IoT, and robotics to enhance precision, efficiency, and predictive maintenance.

- Materials Innovation: Development of new alloys and composites that offer superior strength-to-weight ratios and corrosion resistance.

- Sustainable Manufacturing: Emphasis on eco-friendly processes, waste reduction, and energy-efficient equipment.

- Design for Additive Manufacturing: Hybrid techniques combining CNC machining with 3D printing to produce complex, lightweight parts.

Partnering with reliable china cnc machining parts suppliers like DeepMould.net ensures your business remains at the forefront of these technological advancements, facilitating innovation and competitive advantages.

Conclusion: Elevate Your Business with Top-Quality CNC Machining from China

The metal fabrication industry hinges on the quality, precision, and reliability of machined components. Engaging with china cnc machining parts suppliers offers an exceptional opportunity to access advanced manufacturing capabilities, reduce costs, and uphold strict quality standards. Companies like DeepMould.net exemplify excellence in this domain, providing tailored solutions that meet the evolving demands of metal fabricators globally.

Adopting the right supplier partnerships can unlock new levels of efficiency, innovation, and growth for your business. By prioritizing quality, technological capability, and customer support, your company can thrive in the competitive landscape of metal fabrication, leveraging the strength and precision of China's leading CNC machining parts suppliers.